The world’s growing commitment to sustainable energy solutions has gathered momentum in recent years, with solar power emerging as a leading contender for clean and renewable energy generation. As the demand for solar panels continues to soar, so does the need for innovative manufacturing processes capable of enhancing efficiency, reducing costs, and accelerating production. Enter 3D printing—a technology with the potential to revolutionise the solar panel industry.

How Are Solar Panels Currently Manufactured?

Before delving into the influence of 3D printing, it is crucial to grasp the traditional methods of solar panel manufacturing. Conventional solar panels predominantly rely on crystalline silicon, an immensely efficient photovoltaic material. The manufacturing process encompasses several labour-intensive stages.

Silicon Ingot Growth

The journey begins with high-purity silicon, which undergoes a transformative process of melting and solidification, eventually emerging as large cylindrical ingots. This initial phase is notorious for its resource-intensive and energy-consuming nature, adding a significant layer of cost to production.

Wafer Slicing

Following ingot formation, silicon slices are meticulously carved into thin wafers with the assistance of diamond wire saws. The slicing process invariably generates substantial material wastage, amplifying production costs and material inefficiency.

Cell Production

Wafers subsequently undergo treatment with a cocktail of chemicals and materials to culminate in the creation of solar cells. This stage necessitates precise control and entails the utilisation of potentially hazardous chemicals.

Module Assembly

Solar cells are strategically assembled into panels, shielded with glass, and encased within a protective polymer. This assembly process demands meticulous quality control to ensure the panels’ durability and performance.

The traditional manufacturing method has commendably served the solar industry. However, it grapples with inherent limitations such as material wastage, energy-intensive processes, and a languid production pace. The advent of 3D printing technology heralds innovative solutions to these persistent challenges.

More from Tech

- How Solar Powered Batteries Are Shaping The Future Of Green Energy

- 71% Of People Struggle To Stay Focused Due To Digital Overload

- How To Choose Between A Web App and A Native App

- We’ve Heard Of Smart Homes, But What Is A Smart City?

- Experts Share: What Will Medtech Startups Build Around AI Diagnostic Systems?

- UK vs US: Whose Tech Industry Is Performing Better In 2025?

- Experts Share: How Can Diagnostic AI Be Integrated Into Existing Medtech Systems?

- How Are CRMs Shaping The Future Of B2B Sales?

What Is 3D Printing’s Role in Solar Panel Production?

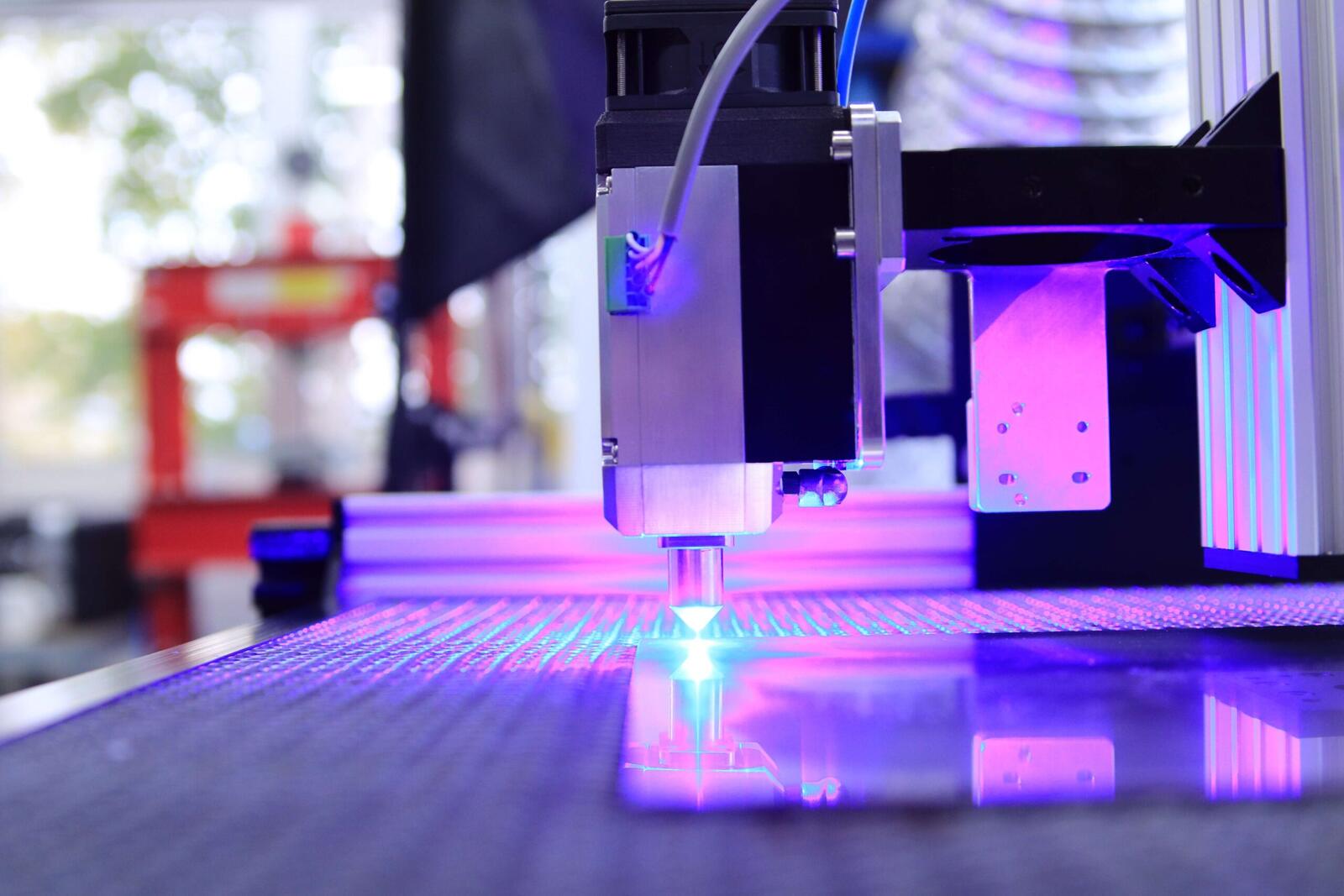

3D printing, colloquially referred to as additive manufacturing, has made noteworthy inroads across various industries owing to its aptitude for crafting intricate geometries with precision and efficiency. When channelled into solar panel production, it unfurls several notable advantages.

Design Flexibility

The hallmark of 3D printing is its capacity for intricate and bespoke designs, enabling the creation of solar panels with unique contours and dimensions tailored to specific installations. This adaptability assumes paramount significance when it comes to integrating solar panels into architectural elements, be it the curvature of building facades or other unconventional surfaces.

Material Efficiency

Traditional solar panel manufacturing perpetuates a substantial trail of material waste, particularly during the slicing of silicon wafers. In stark contrast, 3D printing champions an additive approach—materials are meticulously deposited layer by layer, minimising wastage. The consequential reduction in costs resonates with sustainability goals, aligning manufacturing practices with environmentally conscious ideals.

Enhanced Efficiency

3D printing has the potential to forge intricate microstructures, fine-tuned for optimal light absorption and energy conversion within solar cells. These avant-garde designs hold the promise of significantly amping up the efficiency quotient of solar panels. The end result—higher energy yields from the same surface area.

Rapid Prototyping

3D printing ushers in a nimble era of prototyping and iterative design refinements, drastically curtailing the time needed for the development of novel solar panel models. This expeditious design process not only bolsters manufacturers’ competitiveness in a swiftly evolving industry but also kindles the flames of innovation. Researchers can now experiment with diverse designs, liberated from the constraints of conventional manufacturing methods.

On-Demand Production

With 3D printing, the production of solar panels can be seamlessly tailored to meet specific demand, sidestepping the need for substantial inventories and their attendant storage costs. This just-in-time manufacturing approach streamlines the supply chain and mitigates overproduction, ushering in cost efficiencies while ensuring a prompt response to market dynamics.

Current Applications and Innovations in 3D Printed Solar Panels

A constellation of companies and research institutions has embarked on the journey of exploring 3D printing’s potential within solar panel production.

Flexible Solar Panels

Pioneering researchers have harnessed 3D printing to craft flexible, featherweight solar panels amenable to integration into diverse surfaces, from textiles to plastics. These pliable panels usher in fresh possibilities for portable and off-grid solar applications. Think solar-powered tents, backpacks, or clothing—the frontier of power-on-the-go.

Custom Solar Panels

The customisability afforded by 3D printing has ushered in the era of tailor-made solar panels—precisely engineered to dovetail with the unique demands of a project. Irregularly shaped surfaces find their match, and branding elements can be seamlessly incorporated for architectural integration. Architects and designers, empowered by this flexibility, can seamlessly weave energy-efficient solutions into their blueprints, transforming visions into reality.

Solar-Powered 3D Printers

An intriguing symbiosis between 3D printing and solar energy is witnessed through solar-powered 3D printers. This virtuous cycle leverages solar energy to drive the production of 3D-printed solar components. Not only does this synergy underscore the potential of renewable energy, but it also underscores the adaptability of 3D printing technology in catalysing self-sustaining cycles of innovation.

Advanced Materials

The innovation frontier extends to the development of novel materials compatible with 3D printing, meticulously engineered for solar panel production. These materials are geared toward elevating efficiency, durability, and cost-effectiveness. A deeper exploration of materials holds the promise of breakthroughs, potentially enhancing the efficiency and resilience of solar panels across diverse environmental conditions.

Solar Concentrators

3D printing’s versatility paves the way for the creation of solar concentrators. These ingenious devices amplify the energy output of solar panels by focusing sunlight onto photovoltaic cells with unparalleled precision. As concentrator technology matures, it could find applications spanning both residential and industrial domains, enhancing solar energy generation on a grand scale.

What Are the Challenges of 3D Printing Solar Panels?

Notwithstanding its immense promise, the integration of 3D printing into solar panel production brings forth challenges and considerations that merit acknowledgment.

Material Selection

The meticulous identification of materials compatible with 3D printing and conducive to enduring outdoor exposure stands as a pivotal challenge. Factors such as UV resistance, thermal stability, and electrical conductivity necessitate careful deliberation. Manufacturers find themselves at a crossroads, needing to invest in research to discern materials that align with these criteria, while keeping an eye on cost-effectiveness.

Scale-Up Challenges

Presently, 3D printing in solar panel production predominantly thrives in research and small-scale production domains. Scaling up to cater to the broader solar industry demands mastery over cost-effectiveness, production speed, and robust quality control mechanisms. Manufacturers are compelled to engineer scalable 3D printing processes to facilitate a seamless transition to mass production.

Regulatory Approval

The introduction of novel manufacturing techniques invariably calls for regulatory approval and certification—an often protracted journey. Ensuring the compliance of 3D-printed solar panels with safety and performance standards remains a critical imperative. Manufacturers need to collaborate closely with regulatory authorities to streamline the approval process, enabling the industry’s smooth evolution.

Cost Efficiency

Although 3D printing promises material efficiency, it doesn’t automatically translate to cost savings, especially in the context of small-scale production. The dynamics of economies of scale need to be meticulously considered, ensuring that 3D-printed solar panels can stand toe-to-toe with their traditionally manufactured counterparts in terms of cost-effectiveness. Research and development endeavours must pivot toward optimising production processes for cost efficiency.

Long-Term Durability

Ensuring that 3D-printed solar panels boast a lifespan on par with traditionally manufactured panels represents a critical imperative. The industry grapples with ongoing research to address concerns related to degradation and wear over time. Manufacturers are tasked with the responsibility of subjecting 3D-printed solar panels to extensive testing, validating their long-term performance, and enduring durability.