According to the Enviro Audit Committee, the UK has Europe’s worst fast-fashion habit: we buy 26.7kg of new clothing per person every year.

The problem with fast fashion is that it doesn’t only exist in shops and wardrobes. Clothing requires huge quantities of water and energy to produce, from growing or synthesising fibres to dyeing and distressing fabric. Finished garments are flown around the world. While designers traditionally take six months to move from sketch to shelf, fast fashion outfitter Zara boasts a two-week turnaround.

One way of tackling the impact of fashion is by developing greener fabrics and ways of processing them. Today we’ll look at ten sustainable textile startups changing our wardrobes from the ground up: by developing smarter, cleaner materials to work with.

More from Startups

- Canvas Events: A David and Goliath Story

- The End Of Traditional Startups? Has AI Made Scale Irrelevant?

- How To Secure Startup Funding in the UAE

- Experts Share: How Will The Global Talent Visa Help The Startup Industry?

- Founder of the Week: Christoph Meise

- Fanvue Pioneering ‘Creator AI Monetisation’ On Its Platform: Reshaping The Creator Economy Using AI

- Startup of the Week: Periphery

- MSME Day: How Startups And MSMEs Can Collaborate To Drive Innovation

AlgiKnit

Founders: Tessa Callaghan, Aaron Nesser, Aleks Gosiewski

Country: United States

AlgiKnit‘s kelp-derived materials are rapidly renewable, can be farmed in cold coastal waters around the world and actually improve marine habitats by locking away carbon and cutting out the use of fertilisers and pesticides. The finished materials are durable and practical, just like traditional fabrics, but degrade quickly when sent to composting facilities.

Bolt Threads

Founders: Dan Widmaier, David Breslauer, Ethan Mirsky

Country: United States

Bolt Threads is engineering alternatives to common materials such as silk and leather. Already adopted by Stella McCartney, the sustainable textile startup’s products so far include Microsilk, a textile spun from the same proteins as spiderwebs, and Mylo, a leather alternative made from the root structure of mushrooms.

Denim Dyed Denim

Founders: Professor Xungai Wang, Dr. Rangam Rajkhowa, Dr. Rebecca Van Amber, Dr. Christopher Hurren, Dr. Nolene Byrne

Country: Australia

Denim is one of fashion’s dirtiest textiles: in Xintang, denim hotspot of the world, the water runs indigo and locals suffer respiratory and reproductive issues. Dyeing and distressing denim fabric requires huge quantities of water and is associated with dangerously high levels of heavy metals, according to a 2010 study by Greenpeace.

This project from the Institute for Frontier Materials at Deakin University uses old denim to dye new material and completely cuts out water usage—that’s over 200 litres of water for a pair of jeans. Even more impressively, one pair of old jeans is enough to dye ten new pairs.

ECONYL by Aquafil

Founder: Giulio Bonazzi

Country: Italy

Launched in 2o11, Econyl quickly established itself as an industry leader with its nylon yarn made from recovered fishing nets. Its nylon regeneration system rescues ocean plastics, carpets, fabric scraps and industrial waste and turns them into fibres that are just as pure as virgin nylon; they could potentially be recycled infinitely. Household names Adidas, H&M, Stella McCartney and Prada count themselves among Econyl’s hundreds of brand partners.

Kniterate

Founders: Gerard Rubio, Triambak Saxena

Country: Spain, United Kingdom

Kniterate brings knitwear production back to your neighbourhood through affordable, compact knitting machines. Industrial knitting machines are unwieldy, require trained technicians, take up huge amounts of floor space and cost upwards of $50,000; Kniterate’s machine is straightforward to use, comes with design software and costs less than £10,000. It’s perfect for small fashion labels, community makerspaces and schools.

Orange Fiber

Image: Orange Fiber/H&MFounders: Adriana Santanocito, Enrica Arena

Country: Italy

Italian startup Orange Fiber spins citrus peel into silky, lightweight cellulose yarn that takes dye beautifully and can be made gauzy, opaque, shimmery or matte to spec. Annually, Italy’s fruit juice industry produces around 700,000 tonnes of pastazzo ripe for cellulose extraction; most goes to waste.

Orange Fiber collaborated with compatriots Salvatore Ferragamo to create a sustainable capsule collection in 2017 and its orange silk found its way into fashion giant H&M’s Conscious Exclusive collection for Spring/Summer 2019.

PILI

Founders: Thomas Landrain, Marie-Sarah Adenis, Jérémie Blache, Guillaume Boissonnat

Country: France

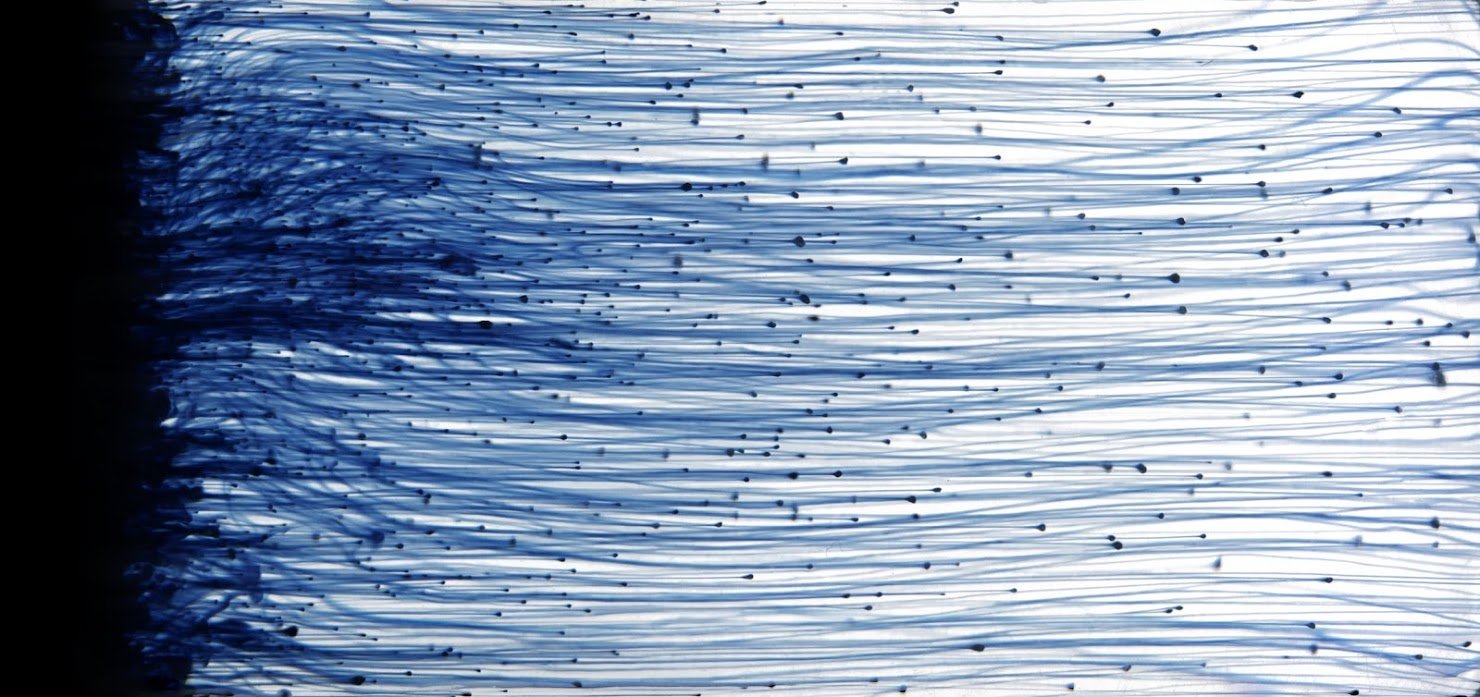

Fabric production usually involves petrochemical dyes, which are cheap and widely available but non-renewable and pollute water streams. Pili uses enzymes and microorganisms to transform sugar into vibrant, fully renewable pigments for textiles through natural processes. When compared to one kilogram of petrochemical dye, one kilogram of Pili dye saves 100kg of crude oil and 10kg of toxic chemicals; it uses five times less water and works at room temperature, where industrial dyes often reach over 300°C.

Piñatex by Ananas Anam

Founder: Dr. Carmen Hijosa

Country: Philippines, United Kingdom

Spanish leathergoods expert Dr. Carmen Hijosa was inspired to develop a sustainable alternative to animal leather after discovering the environmental impact of its production. After years of research and development, Piñatex came into fruition.

Piñatex pineapple leather is vegan and has all the best qualities of animal leather with a vastly reduced footprint. By extracting long fibres from pineapple leaves through a process called decortication, plantation owners are able to reduce waste and create additional income on top of their harvest.

Provenance Biofabrics

Founders: Christian Ewton, Michalyn Andrews

Country: United States

Lab-grown leather may make its way into your wardrobe yet: Provenance Biofabrics is learning to build materials from the bottom up with collagen. In nature, collagen forms cross-links and bundles to form skin and hide; growth and environmental stressors create unique features and distinctive textures. By combining collagen with mechanics, Provenance hopes to recreate all the charm of leather and exotics in an ethical, sustainable way.

Resortecs

Founders: Cédric Vanhoeck, Vanessa Counaert

Country: Belgium

Resortecs has cleverly developed thread that dissolves and unbonds at very hot temperatures, making it easier to dissemble garments for recycling. Companies can separate seams, embellishments and fastenings in moments without any changes in the design or production process, and because the melting point is over 100°C garments can be washed at regular temperatures.